Introduction

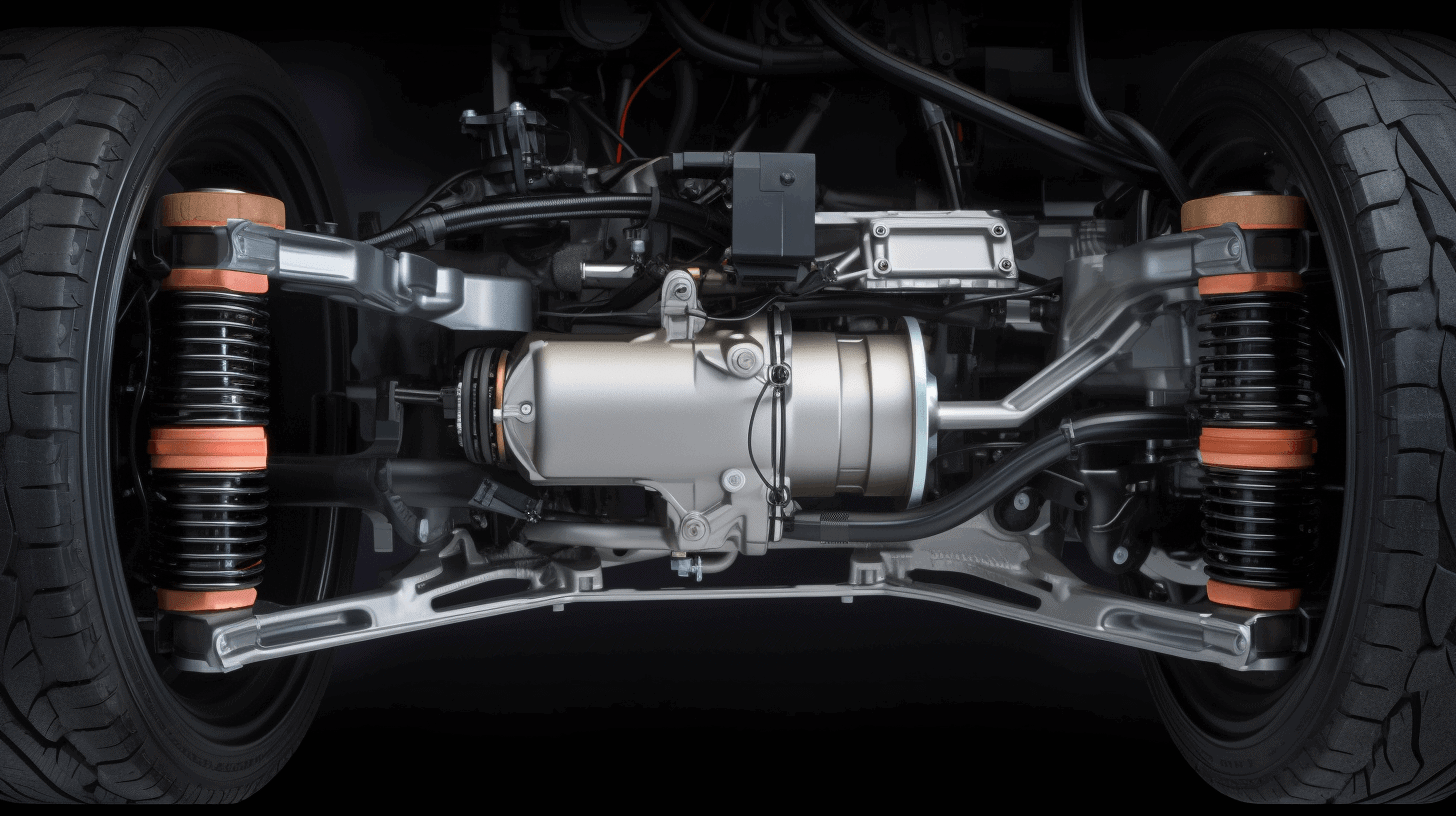

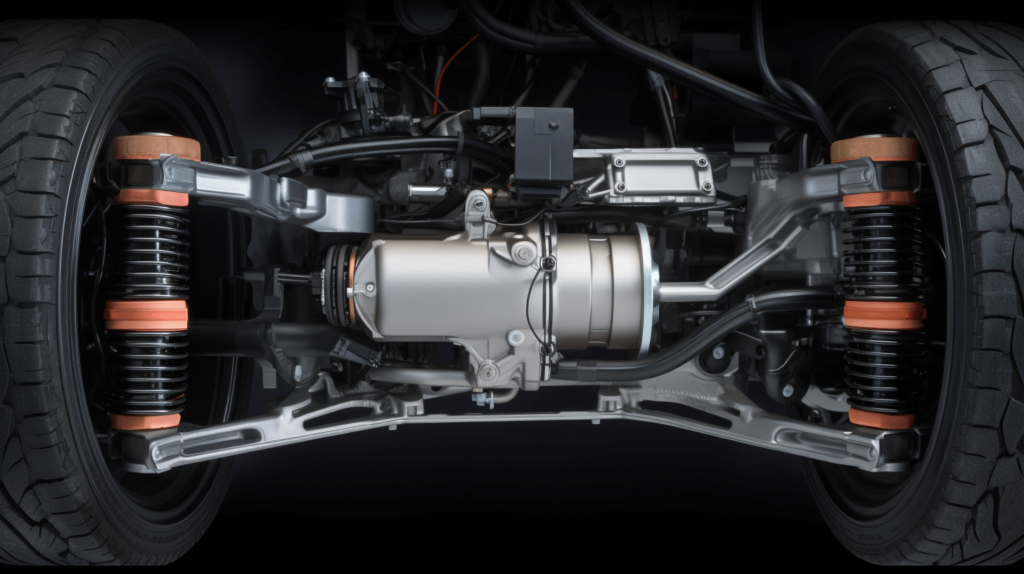

AEG’s new dual structure shock mount system is a design innovation that promises to provide effective shock and vibration mitigation in automotive and industrial applications. This new mount system has been developed to offer varying static properties, dynamic shock and vibration mitigation, and improved life over a wide load range. As a result, it has significant implications for industrial and automotive applications where there is a need for radial damping to protect equipment from shock and vibration damage.

The importance of shock and vibration mitigation in automotive and industrial applications cannot be overemphasized. Shock and vibration can cause significant damage to equipment, leading to premature wear and tear, increased maintenance costs, and downtime. Therefore, there is a need for effective shock and vibration mitigation systems that can protect equipment from such damage.

The purpose of this blog is to explore the design, benefits, and potential applications of AEG’s new dual structure shock mount system. The new mount system is designed to have two hollow spherical elements, with the top element serving as a load-bearing element and the bottom element serving as a vibration shock damping element. This design-formulation concept promises higher axial-radial stiffness, vibration damping, and extended life. Finite element analysis results and prototype testing have demonstrated the optimum stiffness and damping properties for the radial and axial deflection in service conditions.

Recent advances in material technology, processing, and design concepts have made it possible to achieve vibration and shock performance improvement. The dual mount design concept is successfully used in aerospace and marine applications for sound and vibration isolation. Material choices and mount designs are established based on the requirements for the combined axial and radial loads experienced by the current mount systems.

In conclusion, AEG’s new dual structure shock mount system is an innovative solution to the problem of shock and vibration damage in industrial and automotive applications. The potential applications of this mount system are significant, ranging from engine and silent mount design in the automotive industry to construction and heavy equipment industries for increased shock durability. The benefits of this dual mount system are improved reliability, maintainability, acquisition cost, inspection intervals, and design efficiency. It is clear that AEG’s design innovation has significant implications for the field of shock and vibration mitigation.

Design of the Dual Structure Shock Mount System

The design of AEG’s dual structure shock mount system is a breakthrough in shock and vibration mitigation. The mount system is composed of two hollow spherical elements, with the top element serving as a load-bearing element and the bottom element serving as a vibration shock damping element. The two elements work together to offer axial and radial damping, which is crucial in mitigating shock and vibration damage in automotive and industrial applications.

The top spherical element of the dual structure shock mount system is designed to bear the weight of the equipment it supports. It is made of a high-strength material that can withstand heavy loads and provide sufficient stiffness. The bottom spherical element, on the other hand, is designed to dampen shock and vibration. It is made of a material with high damping capacity, such as rubber or elastomer.

One of the advantages of the dual structure system is its ability to provide both axial and radial damping. The combination of the top and bottom spherical elements provides effective damping in all directions, ensuring that the equipment is protected from shock and vibration damage. The dual structure system also has an extended life due to the use of high-quality materials and the careful design of the mount system.

Finite element results and prototype testing have demonstrated the optimum stiffness and damping properties of the dual structure shock mount system. The finite element analysis showed that the mount system provides high axial-radial stiffness and effective damping properties, making it suitable for a wide range of load conditions. Prototype testing has confirmed the effectiveness of the dual structure system in mitigating shock and vibration damage, making it an ideal solution for automotive and industrial applications.

In conclusion, the design of AEG’s dual structure shock mount system is a significant innovation in shock and vibration mitigation. The use of two hollow spherical elements, with the top element serving as a load-bearing element and the bottom element serving as a vibration shock damping element, provides effective axial and radial damping and an extended life. Finite element results and prototype testing have demonstrated the optimum stiffness and damping properties of the system, making it a suitable solution for a wide range of load conditions in automotive and industrial applications.

Material Technology, Processing, and Design Concepts

The development of AEG’s dual structure shock mount system is the result of recent advances in material technology, processing, and design concepts. Advances in material technology and processing have made it possible to use high-strength and high-damping materials in the construction of the mount system, providing improved vibration and shock performance.

The design of the mount system is also crucial in achieving vibration and shock performance improvement. The use of the two-element structural isolation concept, where the top element serves as the load-bearing element and the bottom element serves as the vibration shock damping element, provides effective axial and radial damping. The careful design of the mount system ensures that it can withstand a wide range of load conditions, while still providing effective damping and stiffness.

The two-element structural isolation concept used in AEG’s dual structure shock mount system is not new. It has been successfully used in aerospace and marine applications for sound and vibration isolation. In these applications, the two-element structural isolation concept is used to isolate sensitive equipment from the vibrations and shocks of the surrounding environment. The success of this concept in aerospace and marine applications makes it a natural fit for the automotive and industrial applications that AEG’s dual structure shock mount system targets.

In conclusion, recent advances in material technology, processing, and design concepts have made it possible to develop AEG’s dual structure shock mount system. The use of high-strength and high-damping materials, coupled with the two-element structural isolation concept, provides effective axial and radial damping and an extended life. The two-element structural isolation concept has been successfully used in aerospace and marine applications, making it a natural fit for the automotive and industrial applications that AEG’s mount system targets.

Potential Applications in the Automotive and Industrial Industries

The potential applications of AEG’s dual structure shock mount system extend beyond just the aerospace and marine industries. The system has the potential to revolutionize shock and vibration mitigation in the automotive and industrial sectors as well.

In the automotive industry, the dual structure shock mount system could be used in engine and silent mount design. The system’s ability to provide effective damping and stiffness while withstanding a wide range of load conditions makes it an attractive option for automotive manufacturers looking to improve the performance of their engines and minimize noise and vibration. The benefits of the dual mount system could be felt in passenger cars, commercial vehicles, and even racing cars.

The construction and heavy equipment industries could also benefit from the use of AEG’s mount system. Construction and heavy equipment are subjected to significant shock and vibration loads, leading to reduced equipment life and increased maintenance costs. By using the dual mount system, construction and heavy equipment manufacturers could significantly increase the shock durability of their equipment, extending its service life and reducing maintenance costs.

The benefits of the dual mount system go beyond just improved performance and reduced maintenance costs. The system’s ability to provide effective damping and stiffness also improves reliability and maintainability, reducing equipment downtime and improving overall efficiency. Additionally, the use of the dual mount system could result in a reduced acquisition cost, as manufacturers can reduce the need for additional damping and isolation components.

In conclusion, the potential applications of AEG’s dual structure shock mount system in the automotive and industrial sectors are significant. The system’s ability to provide effective damping and stiffness, while withstanding a wide range of load conditions, makes it an attractive option for manufacturers looking to improve the performance and reliability of their equipment. The system’s benefits, including improved shock durability, reduced maintenance costs, and improved design efficiency, make it a game-changer in the shock and vibration mitigation industry.

Conclusion

AEG’s new dual structure shock mount system represents a significant breakthrough in the field of shock and vibration mitigation. The two hollow spherical elements, combined with recent advances in material technology and processing, provide effective damping and stiffness while withstanding a wide range of load conditions. The system’s ability to reduce maintenance costs, improve reliability and maintainability, and increase shock durability makes it an attractive option for manufacturers in the automotive and industrial sectors.

In the automotive industry, the dual mount system could improve engine and silent mount design, while in the construction and heavy equipment industries, it could significantly increase the shock durability of equipment. The benefits of the system extend beyond just improved performance and reduced maintenance costs, as it also offers improvements in reliability and design efficiency, as well as reduced acquisition costs.

The importance of shock and vibration mitigation in industrial and automotive settings cannot be overstated. The damaging effects of shock and vibration loads can lead to equipment failure, increased maintenance costs, and reduced productivity. By using the dual structure shock mount system, manufacturers can effectively mitigate these issues, resulting in increased equipment life and improved performance.

Looking to the future, AEG’s design innovation is likely to have significant implications for the field of shock and vibration mitigation. As technology and material science continue to advance, it is likely that new design concepts and structures will emerge, further improving the performance and efficiency of shock and vibration mitigation systems.

In conclusion, AEG’s dual structure shock mount system is a game-changer in the field of shock and vibration mitigation, offering significant benefits to manufacturers in the automotive and industrial sectors. The potential applications of the system are wide-ranging, and the future prospects and implications of AEG’s design innovation are exciting.