Introduction

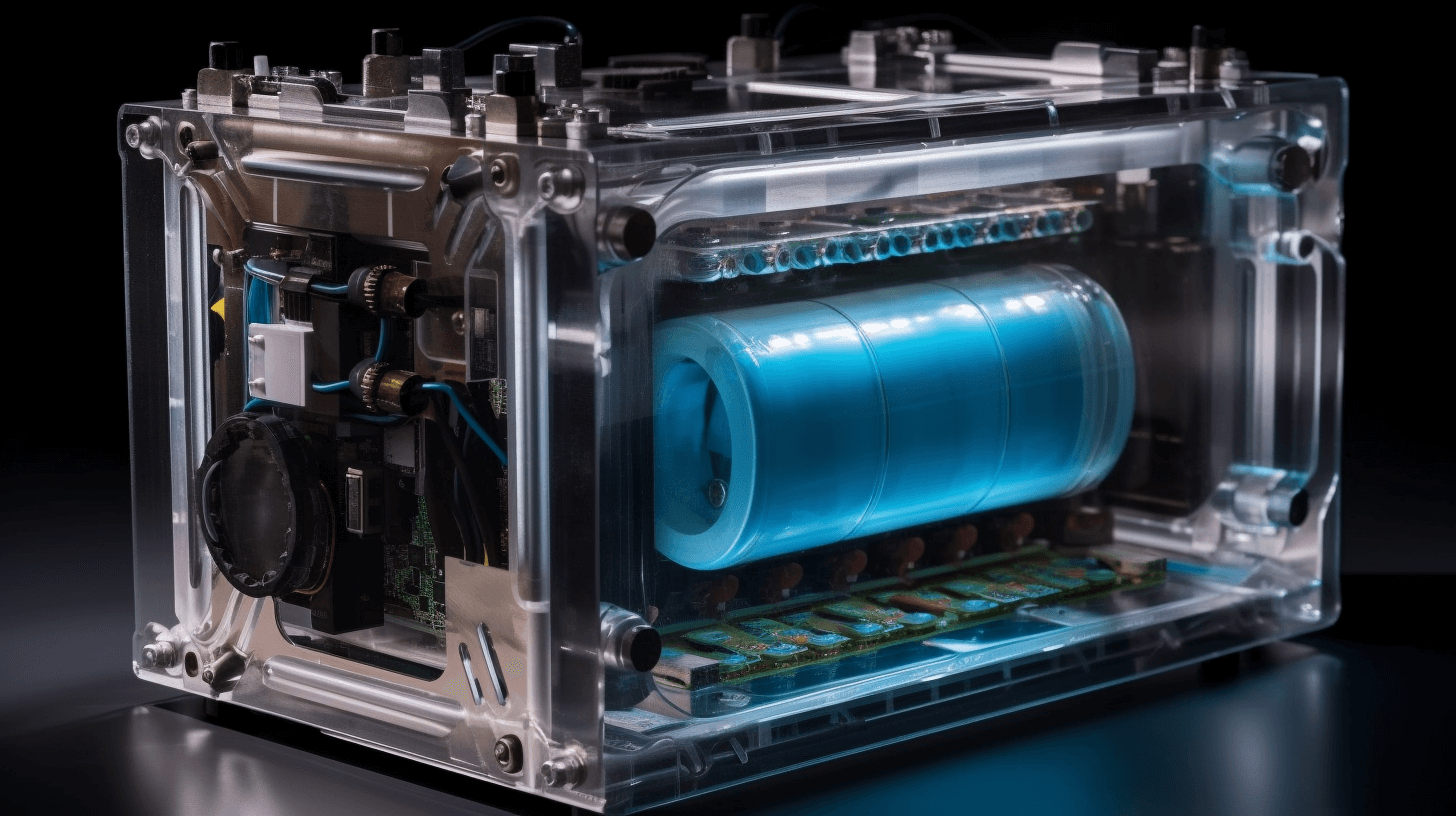

Fuel cells are an essential component of clean energy systems, and their efficiency and reliability depend largely on the quality of their components. One critical element of fuel cell technology is the seals that prevent leaks and maintain proper operation of the system. The development of nanocomposite double lip seals represents a significant breakthrough. These seals are based on nanotechnology and are designed to maintain high sealing force retention in fuel cell thermal cycling environments with vibration loads.

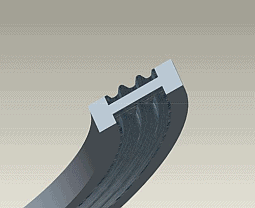

The double lip seal has a primary and secondary sealing surface, and it is made from an EP terpolymer-based elastomer formulation that contains a nano-blowing agent. This agent enables the seal to maintain its sealing force over extended periods of use, even in harsh operating conditions. Compared to other elastomers, this nanocomposite elastomer has excellent resistance to creep and fatigue, good flexibility and clear film, and excellent chemical and UV resistance. Furthermore, AEG’s proprietary steam post-curing protocol allows for the extraction of all un-reacted catalysts/monomers and the activation of the nano-blowing agent in the EP terpolymer system, resulting in a highly durable and reliable seal.

The importance of the nanocomposite double lip seal in fuel cells cannot be overstated. They operate under extreme conditions, with high pressures, temperatures, and chemical exposure. The seals must be able to withstand these harsh environments while maintaining their integrity and performance. The use of nanocomposite double lip seals ensures that they can operate reliably over their entire lifespan, without any leakage or failure.

American Engineering Group (AEG), based in Akron, OH, is a leading developer and supplier of nanocomposite double lip seals for fuel cell applications. Their seals are designed using advanced engineering tools and undergo rigorous testing to ensure their reliability and performance. AEG’s ISO 9001/TS 16949 registered seal manufacturing facilities in India use advanced quality/value improvement programs to continually enhance customer satisfaction. AEG’s technology-driven approach to seal design and development ensures that their seals meet the demands of the most challenging applications.

Features of Nanocomposite Double Lip Seal

The Nanocomposite Double Lip Seal is a remarkable innovation in fuel cell technology. This unique sealing technology is designed with a primary and secondary sealing surface that ensures a high level of sealing force retention in fuel cell thermal cycling operational environments with vibration loads. The EP terpolymer based elastomer formulation of the seal is infused with a nano-blowing agent that helps maintain this high level of sealing force retention over a long period. This feature is particularly important as fuel cells require stable and long-lasting seals to operate effectively.

Moreover, the Nanocomposite Double Lip Seal is highly adaptable to various planar fuel cell designs, making it a versatile solution for different fuel cell applications. The seal’s excellent resistance to creep and fatigue further ensures that it remains functional for extended periods with good flexibility and clear film. Additionally, the seal has low NBS smoke generation, high heat resistance, and excellent chemical resistance with good UV and weather resistance.

Overall, the features of the Nanocomposite Double Lip Seal make it an indispensable component of modern fuel cell technology. The seal’s unique design and properties ensure optimal fuel cell performance and longevity, making it a critical component of their system. With the nanocomposite double lip seal, fuel cell technology can be leveraged to create more efficient and sustainable energy solutions.

The American Engineering Group (AEG) is a company that specializes in creating innovative sealing solutions for various industries, including fuel cell technology. The development of the Nanocomposite Double Lip Seal is a testament to AEG’s commitment to pushing the boundaries of technology to provide reliable and efficient sealing solutions for its customers.

Benefits of Nanocomposite Double Lip Seal

The nanocomposite double lip seal has a number of noteworthy features that make it an ideal choice for fuel cell applications. One of the most significant advantages is its ability to reduce “electrode poisoning” in the fuel cell system, which can improve overall system efficiency and longevity.

In addition, this seal offers excellent chemical resistance and good UV and weather resistance, making it a durable and long-lasting option for fuel cell use. The clear film and good flexibility of the elastomer formulation also make it easy to work with and integrate into a variety of fuel cell designs.

Another important aspect of this nanocomposite double lip seal is AEG’s proprietary steam post-curing protocol. This unique process allows for optimal performance of the seal by extracting all un-reacted catalysts/monomers and activating the nano-blowing agent in the EP terpolymer system. This ensures that the seal maintains high “long-term” sealing force retention even in a fuel cell thermal cycling operational environment with vibration loads.

Overall, the nanocomposite double lip seal offers a number of benefits over other seal materials, making it a top choice for fuel cell applications. Its ability to resist creep and fatigue, low NBS smoke generation, and high heat resistance all contribute to its superior performance and durability. With AEG’s technology-driven design tools and commitment to quality improvement programs, customers can trust that they are getting the best possible seal design for their fuel cell stack.

Design Tools and Quality/Value Improvement Programs

AEG not only provides the cutting-edge nanocomposite double lip seal technology but also offers various design tools and quality/value improvement programs. Their technology-driven design tools help customers to achieve optimum sealing on their fuel cell stack design using various analysis such as “Volume fill” analysis, compression tolerance stack-up analysis, lateral tolerance stack-up analysis, DFMEA, and Finite Element Analysis using a 3D CAD. These tools help to ensure that the seal is perfectly matched to the specific requirements of each individual customer’s fuel cell design.

Furthermore, AEG’s Indian seal manufacturing facilities are ISO 9001/TS 16949 registered, ensuring that customers can trust in the quality of the nanocomposite double lip seals they receive. Additionally, AEG is committed to continuously improving customer satisfaction through the implementation of new seal technology and various quality/value improvement programs, such as lean manufacturing/Kaizen initiatives, TQM studies, APQP studies, and Six Sigma scrap & cost reduction programs.

With the help of these design tools and quality/value improvement programs, AEG’s nanocomposite double lip seals can achieve optimal performance and reliability in various fuel cell applications. AEG’s proprietary steam post-curing protocol allows for optimal performance of the nanocomposite double lip seal, ensuring that it maintains its sealing force retention and excellent resistance to creep and fatigue in a fuel cell thermal cycling operational environment.

In conclusion, AEG’s nanocomposite double lip seal technology, along with their design tools and quality/value improvement programs, offers a comprehensive solution for customers looking to achieve optimal sealing performance in their fuel cell applications.

Conclusion

In summary, the nanocomposite double lip seal developed by American Engineering Group (AEG) offers several advantages for fuel cell applications. Its primary and secondary sealing surfaces, EP terpolymer based elastomer formulation with nano-blowing agent, and high “long-term” sealing force retention in a fuel cell thermal cycling operational environment make it an ideal solution for various planar designs. Additionally, this seal shows less “electrode poisoning”, excellent chemical resistance with good UV and weather resistance, clear film, and good flexibility.

AEG’s proprietary steam post-curing protocol enables optimal performance of this technology, and their design tools including “Volume fill” analysis, compression tolerance stack-up analysis, lateral tolerance stack-up analysis, DFMEA, and Finite Element Analysis using a 3D CAD ensure that the fuel cell seal is designed to meet the specific needs of each application. Furthermore, AEG’s Indian seal manufacturing facilities are ISO 9001/TS 16949 registered and they constantly strive to improve customer satisfaction through the implementation of new seal technology and quality/value improvement programs such as lean manufacturing/Kaizen initiatives, TQM studies, APQP studies, and Six Sigma scrap & cost reduction programs.

It is evident that the nanocomposite double lip seal offers several benefits for fuel cell applications, and working with AEG to design a cost-effective fuel cell seal using this technology could be a valuable investment for companies in the fuel cell industry. Their development engineers have the expertise to provide optimum sealing on the customer fuel cell stack design, and their commitment to quality and continuous improvement ensures that customers receive the best possible solutions.