Introduction

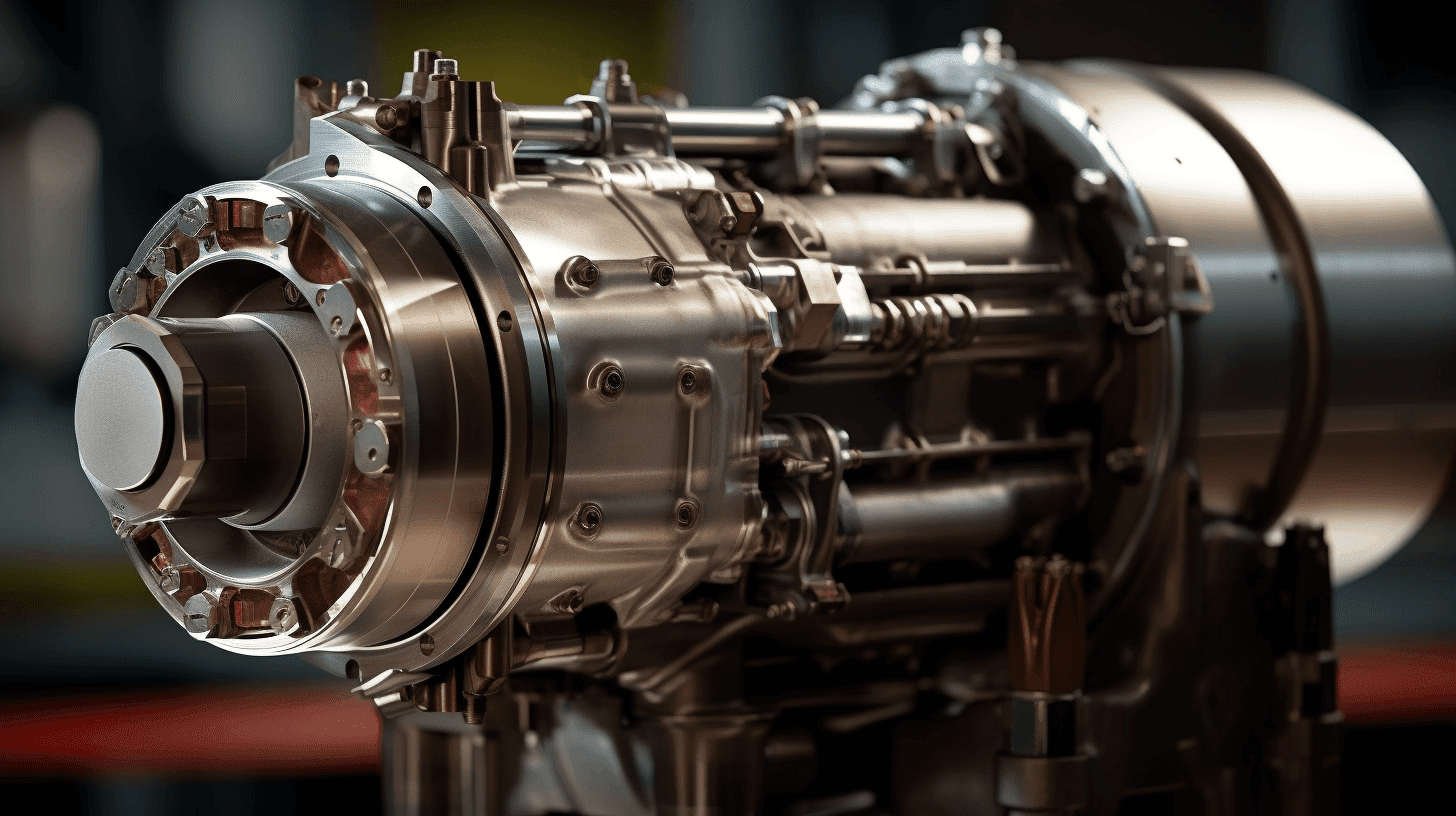

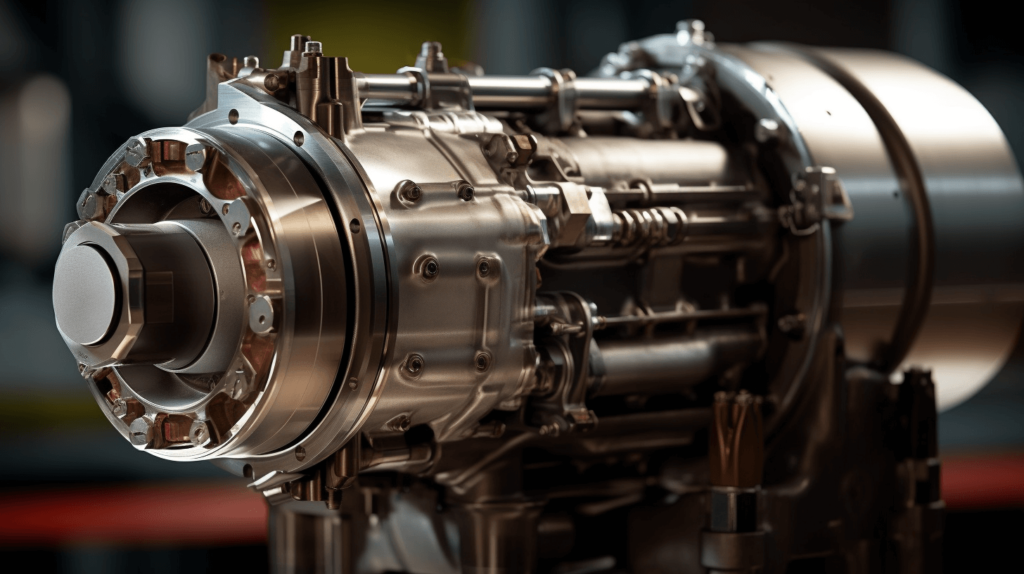

The AEG Dual Elastomer Torsional Vibration Damper System is an innovative solution for vibration mitigation and shock in a wide range of applications in the automotive and industrial sectors. This system is designed to provide both axial and radial damping by utilizing a dual-structure system with two elastomer elements. The top element functions as a vibration damping element, while the bottom spherical elastomer element is responsible for noise and harshness damping.

The AEG Dual Torsional Vibration Damper System includes a soft viscous bushing hub and an inertia ring. The soft viscous bushing hub is designed to be rigidly connected to a drive shaft, while the inertia ring is connected to the hub through a thin polyurethane material layer. This unique design allows for torsional vibration reduction of the crankshaft system on multi-cylinder engines for vehicles. AEG polyurethane torsional vibration dampers are designed to provide a significant reduction of sound and vibration in various types of powertrain systems, protecting engine and transmission components from excessive wear.

One of the significant benefits of the AEG Torsional Damper System is the reduction of gear NVH and wear in transmission. By reducing torsional vibration, component life is increased while providing greater operator comfort and better service life. The self-aligning spherical hub also eliminates concentricity concerns, further enhancing the performance and reliability of the system.

Overall, the AEG Dual Elastomer Torsional Damper System offers a unique solution for enhancing vibration mitigation in automotive and industrial applications. Its dynamic shock and vibration mitigation over a wide load range make it an excellent choice for applications in truck, off-road vehicle, marine, agricultural, and military vehicle engines. With a torsional stiffness capacity of up to 900ft-lbs, this system provides an effective solution for reducing noise and vibration in powertrain systems while protecting critical engine and transmission components.

AEG Dual Torsional Damper System Design

The AEG Dual Torsional Damper System is designed to offer superior shock and vibration mitigation over a wide load range for automotive and industrial applications. This system utilizes a dual-structure system that provides both axial and radial damping. The dual structure system consists of two elastomer elements, each with a unique function.

The top elastomer element of the AEG Dual Torsional Damper System functions as a vibration damping element, effectively reducing vibration and providing smoother operation. The bottom spherical elastomer element is responsible for noise and harshness damping, further enhancing the performance of the system. By utilizing two elastomer elements, the AEG Dual Torsional Damper System offers dynamic shock and vibration mitigation, making it an ideal solution for a wide range of applications.

The AEG Dual Torsional Damper System also includes a soft viscous bushing hub and an inertia ring. The soft viscous bushing hub is designed to be rigidly connected to a drive shaft, while the inertia ring is connected to the hub through a thin polyurethane material layer. This unique design allows for torsional vibration reduction of the crankshaft system on multi-cylinder engines for vehicles. The polyurethane elastomer torsional damper reduces torsional vibration, which contributes to gear NVH and wear in transmission.

Furthermore, the self-aligning spherical hub of the AEG Dual Torsional Damper System eliminates concentricity concerns, ensuring maximum performance and reliability of the system. The system also has a torsional stiffness capacity of up to 900ft-lbs, making it suitable for a range of applications that require high-performance torsional damping and vibration-eliminating solutions.

In conclusion, the AEG Dual Torsional Damper System is designed with a dual-structure system that includes two elastomer elements with distinct functions, a soft viscous bushing hub, and an inertia ring. This unique design enables the system to provide dynamic shock and vibration mitigation, making it ideal for applications in truck, off-road vehicle, marine, agricultural, and military vehicle engines. By reducing torsional vibration, component life is increased, while providing greater operator comfort and better service life.

Performance of AEG Torsional Damper System

The AEG Torsional Damper System is designed to provide significant reduction of sound and vibration in various types of powertrain systems. By reducing torsional vibration, the system protects engine and transmission components from excessive wear, ensuring longer component life. Additionally, the AEG Torsional Damper System offers increased operator comfort, reducing operator fatigue and improving overall service life.

The AEG Torsional Damper System’s unique design enables it to be a desirable solution for a wide range of applications, including truck, off-road vehicle, marine, agricultural, and military vehicle engines. Its torsional stiffness capacity of up to 900ft-lbs makes it an ideal solution for applications that require high-performance torsional damping and vibration-eliminating solutions.

Furthermore, the AEG Torsional Damper System’s dual mode torsional damper, featuring a patent-pending design, enhances its performance, making it stand out in the market. The system’s viscous soft elastomer spherical hub effectively eliminates transmission noise, while the polyurethane elastomer torsional damper reduces torsional vibration, contributing to gear NVH and wear in the transmission.

The self-aligning spherical hub of the AEG Torsional Damper System eliminates concentricity concerns, ensuring maximum performance and reliability of the system. This unique feature further enhances the system’s overall performance, making it a top choice for a wide range of applications.

In conclusion, the AEG Torsional Damper System is designed to provide superior shock and vibration mitigation over a wide load range, making it a desirable solution for various automotive and industrial applications. Its ability to reduce sound and vibration, increase component life, and protect engine and transmission components from excessive wear make it an ideal solution for truck, off-road vehicle, marine, agricultural, and military vehicle engines. The system’s unique dual structure design, featuring two elastomer elements with distinct functions, a soft viscous bushing hub, and an inertia ring, further enhances its performance, making it stand out in the market.

Benefits of AEG Torsional Damper System

The AEG Torsional Damper System offers a host of benefits that make it a desirable solution for various automotive and industrial applications. One of the key benefits of the system is its ability to provide dynamic shock and vibration mitigation over a wide load range. This feature ensures that the system can handle a range of loads and maintain optimum performance, even under challenging conditions.

In addition, the AEG Torsional Damper System features both axial and radial damping capabilities, further enhancing its performance. This dual structure system enables the system to provide both axial and radial damping, making it an ideal solution for applications where both types of damping are required.

Furthermore, the system’s polyurethane elastomer torsional damper is designed to reduce gear NVH and wear in the transmission, ensuring longer component life and improved performance. The spherical soft viscous bushing hub eliminates transmission noise, further enhancing operator comfort.

The AEG Torsional Damper System’s self-aligning spherical hub eliminates concentricity concerns, ensuring maximum performance and reliability of the system. This unique feature further enhances the system’s overall performance, making it a top choice for various applications.

Finally, the AEG Torsional Damper System has a torsional stiffness capacity of up to 900ft-lbs, making it an ideal solution for applications that require high-performance torsional damping and vibration-eliminating solutions.

In summary, the AEG Torsional Damper System provides a range of benefits that make it a desirable solution for various automotive and industrial applications. Its ability to provide dynamic shock and vibration mitigation over a wide load range, axial and radial damping capabilities, reduction of gear NVH and wear in the transmission, self-aligning spherical hub, and high torsional stiffness capacity make it a top choice for applications that require superior performance and reliability.

Conclusion

In summary, the AEG Dual Elastomer Torsional Damper System is an innovative solution for the reduction of sound and vibration in powertrain systems, while simultaneously increasing the component life and operator comfort. The system’s design is based on a dual structure system that provides both axial and radial damping. It includes two elastomer elements, with the top element functioning as a vibration damping element, and the bottom spherical elastomer element as a noise and harness damping element. The soft viscous bushing hub and the inertia ring reduce torsional vibration that contributes to gear NVH and wear in transmission. The system also features a self-aligning spherical hub that eliminates concentricity concerns and has a torsional stiffness of up to 900ft-lbs of torque capacity.

The benefits of the AEG Dual Elastomer Torsional Damper System are vast. The system provides dynamic shock and vibration mitigation over a wide load range, which is essential for automotive and industrial applications. It reduces gear NVH and wear in transmission, protects engine and transmission components from excessive wear, and provides greater operator comfort and better service life. The self-aligning spherical hub is also a significant advantage since it eliminates concentricity concerns.

Vibration mitigation is of utmost importance in automotive and industrial applications. The AEG Dual Elastomer Torsional Damper System is an excellent solution that has a lot of potential for future development and improvement. As technology advances, there is no doubt that this system will continue to evolve and provide even more efficient and effective vibration mitigation solutions.

In conclusion, the AEG Dual Elastomer Torsional Damper System is a significant innovation in the field of vibration mitigation. Its design, features, and benefits make it an ideal solution for various automotive and industrial applications. As technology advances, there is no doubt that this system will continue to improve and play a crucial role in reducing sound and vibration in powertrain systems.